Pumps generate the energy in the entire irrigation system.

Despite their importance, they are one of the most misunderstood components within the entire irrigation system.

Since commercial drip irrigation systems require a certain pressure to operate (often above 15 psi at the drip emitter), we need a specific type of pump that can produce a high pressure at high flow rates.

| Pump | Application |

| Centrifugal Pump | • Commercial Drip Irrigation (pressure compensated) • Facility-wide water delivery • High pressure, high flow applications |

| Mag Drive Pump | • Recirculating in a day tank • Transfer between tanks • Small drip irrigation (open flow) • Ebb and flow • Low pressure, variable flow applications |

| Submersible Pump | • Recirculation in a day tank • Transfer between tanks • Small drip irrigation (open flow) • Sump pumps • Temporary applications • Low pressure, high flow applications |

Centrifugal pumps

These are the most commonly used pumps in commercial drip irrigation applications due to the fact that they are reliable, quiet, easy to install, and most importantly, extremely powerful!

One of the most common questions we get is ‘can this pump run this system’. That can be a difficult question to answer, but some general tips are:

- Centrifugal pumps are required for large drip systems. Period. If you have more than 200 square feet of growing area, you will likely need a centrifugal pump.

- Mag drive pumps can work great for transferring large volumes of water or fertilizer, but they do not produce much pressure. These pumps are best for a small system without pressure compensating emitters.

- Submersible pumps (with the exception of the ECODIVER series, which is centrifugal) will also not be capable of producing the high pressure required for drip irrigation.

Improperly sized pumps, which impact the efficiency of a system enormously, are all too common in poorly designed irrigation systems. Proper pump selection is critical for the success and longevity of any irrigation system.

Selecting the correct pumps for your facility can be quite overwhelming but our team is here to help you make that decision and provide guidance on keeping your pumps and system running smoothly. Sizing a pump is a difficult task requiring experience and know-how. We’ll cover that in-depth another time. For now, here are some of the most important centrifugal pump features HGC offers:

Variable Frequency Drives

A pump that is too large will be working very hard in order to deliver very little flow to the system. Without adequate flow, the pump’s motor can potentially overheat (most pumps use the water flow to cool themselves). This drastically reduces the lifespan of your pump.

One very easy way to avoid this issue is to use a pump equipped with a variable frequency drive (VFD). Pumps equipped with a VFD are able to throttle down the speed at which the impeller spins, allowing them to match the needs of the system without wasting excess energy.

The DAB E.SYBOX and DAB E.SYBOX MINI3 are both equipped with VFDs, meaning they are extremely efficient, only using the energy required for the task at hand, no more.

Pressure Switch

A pressure switch is an electronic device that turns a pump on and off when a certain pressure is reached. This allows a pump to operate without external controls such as an irrigation timer telling it to turn on or off. It does not matter if the pressure drops because a manual ball valve, electric solenoid valve, or hose bibb opens, the pump will detect the pressure drop and turn on, giving uninterrupted pressure and flow to the system.

Once the valve closes, the pressure builds to a preset amount (often 40, or 50 PSI) and then shuts the pump off, preventing any overheating or damage from a no-flow situation.

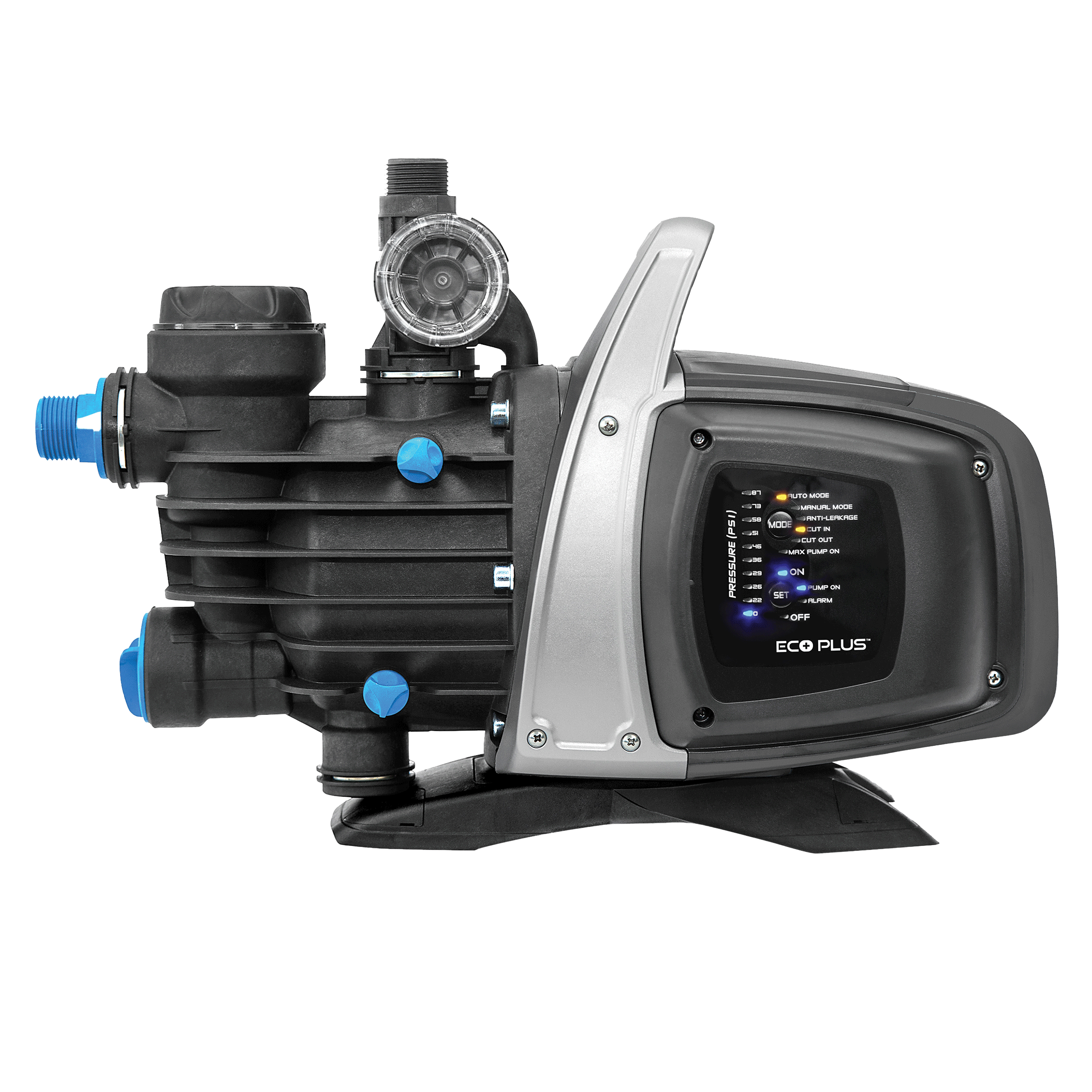

The DAB E.SYBOX and Mini3, mentioned above, both have this feature. More pumps that have this feature include the ECOTRONIC series and the ECO Plus Elite Electronic Series.

Leak Detection

If a pump has a pressure switch installed and there is a small leak somewhere in the system, this will result in a phenomenon known as pump cycling. The pump will automatically shut-off at the preset pressure value of say 50 PSI, but the leak in the system will cause this pressure to decrease. Once the pressure drops below the ‘cut-in’ point, the pump will turn back on again, but only for a brief period to repressurize the system. If you have a pump that turns itself on for 5-10 seconds when everything is shut off, you may have a leak!

If a pump has a pressure switch installed and there is a small leak somewhere in the system, this will result in a phenomenon known as pump cycling. The pump will automatically shut-off at the preset pressure value of say 50 PSI, but the leak in the system will cause this pressure to decrease. Once the pressure drops below the ‘cut-in’ point, the pump will turn back on again, but only for a brief period to repressurize the system. If you have a pump that turns itself on for 5-10 seconds when everything is shut off, you may have a leak!

Overheat Protection

Like many electronics, overheating is catastrophic to pump motors. This is why a thermal protection device is included in every centrifugal pump that Hawthorne distributes. If the pump motor exceeds a preset temperature it will shut off, protecting the pump and facility from damage or fire!

“Dumb” Centrifugal Pumps

So, you don’t need any of that fancy electronic stuff, you just want a pump that turns on and off? Dumb pumps are pumps too, as we say in the irrigation department. We have you covered! These pumps will require you to manually plug them in or flip the switch to operate them. They can also be controlled using a relay switch connected to a standard irrigation controller (24VAC to 120VAC for these pumps).

(Dumb submersible

centrifugal pump!)

Wrapping It Up

We’ve been on a journey from the plant all the way back to the pump, the originator of the entire system’s energy. We hope that this has helped demystify what is often an overlooked, but essential piece in every grow facility. Contact Hawthorne for our support and guidance. We’re here to help you, from your basement grow to the largest greenhouse, achieve success by implementing irrigation best practices.

Continue learning with more drip irrigation system design tips ⟶

The Hawthorne Difference

Our team of technical experts can help not only with the specifics on setting up a drip irrigation system, but also with the holistic, complex interplay between irrigation and other areas of your grow, including nutrients, growing media, HVAC and lights. Our goal is to provide growers the information they need to make the right decisions for their facilities, the first time.

The products and advice to keep you in the game

Hawthorne Gardening Company, in partnership with some of the largest irrigation equipment manufacturers in the world, is here to help you maximize your crop’s potential with the best irrigation management strategies and information available today.

Our dedicated team can assist you in every step of the way to ensure that your system will work exactly how it is supposed to from day one.

For more information, call Hawthorne at 888-808-4826 or fill out the form below.