A critical question in drip irrigation is how to ensure the first plant on a table gets the same amount of water and nutrients as those at the end of the table. This is where pressure compensation comes in.

As liquid moves through a pipe, it gradually loses energy to friction. Friction is the resistance to motion of one object moving relative to another. For example, when you slide across a tiled floor in new socks, friction is the force that brings you to a stop. When pressurized liquid is forced through a tube in a drip irrigation system, friction is constantly opposing the movement of the liquid.

It’s not exactly the same as sliding across the tile, because the liquid is not slowed down by friction when it is pressurized in a tube/pipe (for reasons we won’t get into here). This energy loss has to go somewhere, and that somewhere is the pressure!

Example

Let’s say you have a 500 foot long section of perfectly straight ¾” (three-fourths-inch) schedule 40 PVC pipe and you want to push 8 gallons per minute (GPM) through it.

You install an Eco Plus Elite 3/4HP Electronic Multistage Pump to the system and turn it on. The built-in pressure gauge on the pump’s electronic controller reads 51 PSI of pressure.

At the other end of that pipe you install a pressure gauge, and it reads 25.4 PSI of pressure.

Why the difference? Pressure loss. This is another reason thoughtful irrigation design is so important. If you use the wrong size pipe, pressure loss increases exponentially. Using 1” PVC instead of ¾” PVC could mean the difference between a functioning and non-functioning system.

Why pressure loss matters

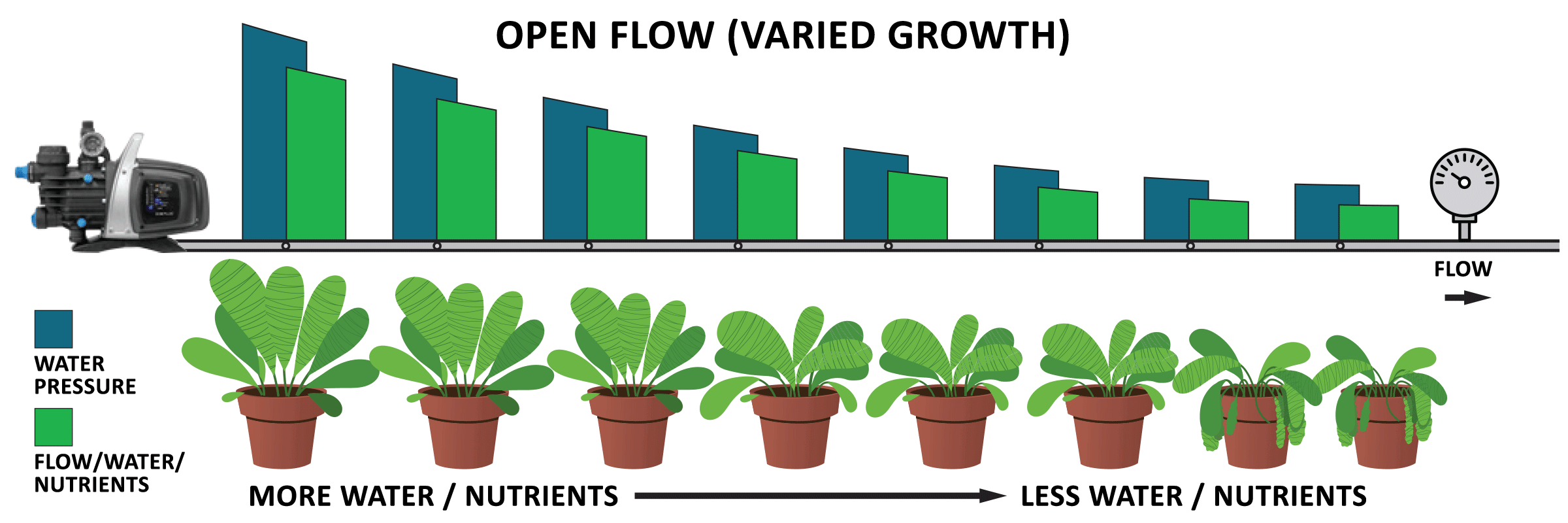

Liquid in a pipe will have a pressure gradient form along the length of it. This is not ideal when we want to evenly distribute water (and nutrients) to a crop, because without the benefits of pressure compensation, pressure will directly affect the flow at a given point.

Continuing the example above, if we punched a small hole in PVC where the pressure in the pipe was 50 PSI, more water would leak than if we punched the same sized hole in the pipe at 30 PSI. This is a problem when we are growing crops, because that pressure gradient will mean more water (and nutrients) will end up in the pots closest to the pump, while plants at the other end of your grow room are at a high risk of drought stress.

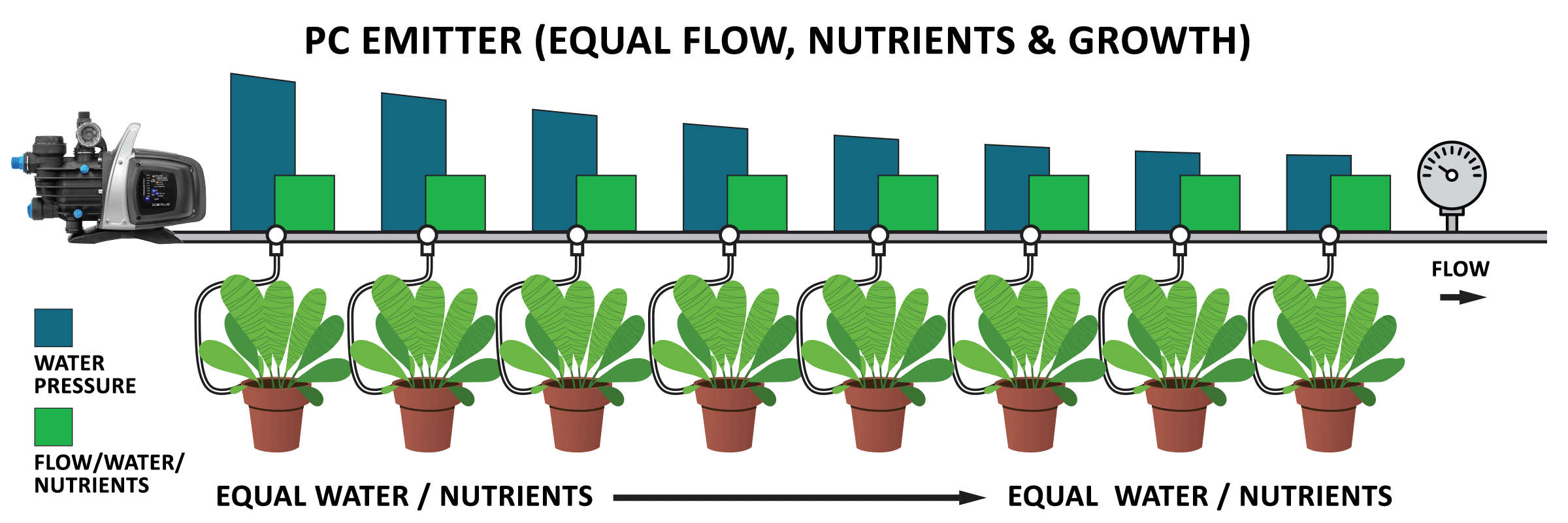

Pressure compensation (PC) can help. Emitters with this technology will provide the exact same flow so long as the pipe is within a certain pressure range. No more misfed plants, only even growth and uniform canopies.

This is why we use PC emitters for commercial applications. You can get away with open flow if you have a few plants close together, because there will be little or no pressure (and therefore flow) difference between them. But for large commercial grows, uniformity from pressure compensation is critical to helping cultivators grow consistent, profitable crops.

Special Note On Spray vs. Drip Stakes:

When growing with large pots, either because of cultivation style or preference, drippers might not be recommended. Depending on the pot size, each pot might require upwards of six drippers for even watering.

For those situations, we recommend spray stakes instead of drip stakes, like those from top-selling Netafim™. These feature pressure compensating emitters so you get the benefits of drip irrigation, with the coverage of a sprayer.

A well-designed drip irrigation system:

- Features the ability to alter the frequency and duration of irrigation events

- Delivers uniform flow rate and total amount of water and nutrients to each individual plant

- Includes the ability to provide targeted water programs for each plant growth- or crop-stage

- Provides adequate water supply or storage to maintain consistent irrigation

- Can help minimize costly wastewater removal or treatment

- Can help minimize humidity load for indoor growing operations, thus helping to reduce dehumidification load

The primary goal of any irrigation system is to deliver water and nutrients to your plants in a consistent, uniform fashion. This can help maximize total crop yield, and reduce the risk of pest and disease pressure in soilless media. The design and management of your irrigation system is integral to maximizing crop output.

Stay tuned for part 2

This concludes part 1 of our exploration into drip irrigation. Be sure to follow us on social media and check our website to be among the first to know when we release part 2.

The Hawthorne Difference

Our team of technical experts can help not only with the specifics on setting up a drip irrigation system, but also with the holistic, complex interplay between irrigation and other areas of your grow, including nutrients, growing media, HVAC and lights. Our goal is to provide growers the information they need to make the right decisions for their facilities, the first time

The products and advice to keep you in the game

Hawthorne Gardening Company, in partnership with some of the largest irrigation equipment manufacturers in the world, is here to help you maximize your crop’s potential with the best irrigation management strategies and information available today.

Our dedicated team can assist you in every step of the way to ensure that your system will work exactly how it is supposed to from day one.

For more information, call Hawthorne at 888-808-4826 or fill out the form below.